Bearings for Industrial Electric Motors & Generators

ZZ has a long and vast experience in the electric motor industry as well as in most of the industries where electric motors and generators are used. In this highly competitive industry, the profound knowledge of ZZ has been used to develop solutions to meet the ever increasing demands for higher quality, shorter delivery time, lower noise levels and improved technical support.

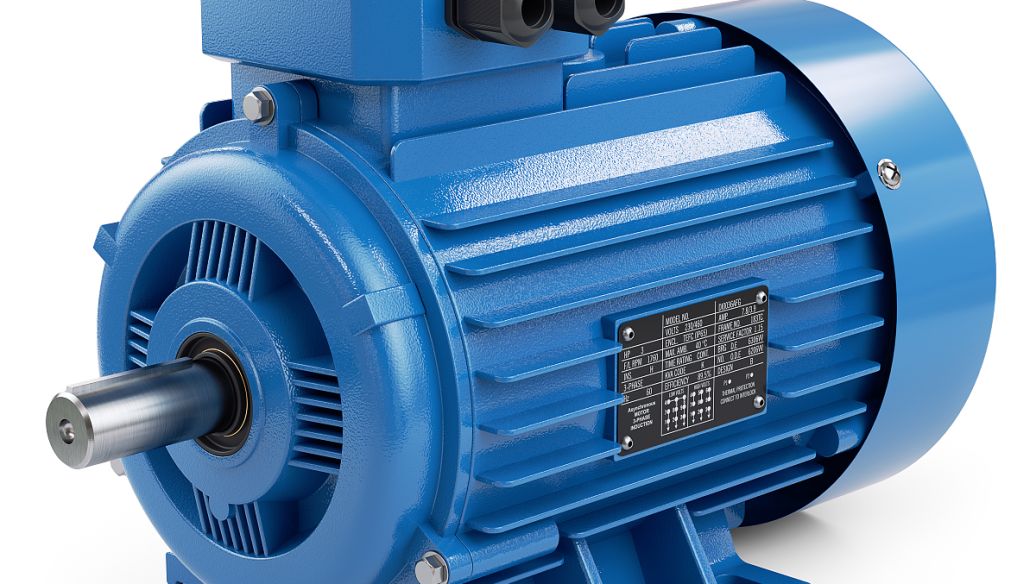

Motors for specific applications are high volume products, which are typically small to medium sized, ranging from 1 to 500 KW. These motors are used within specific applications e.g. fans, pumps and compressors where the reliability and trouble-free operation of the motor are of high importance. Also generators have to cope with the same or even tougher needs. The three-phase induction motor is a robust and maintenancefree solution that is the most commonly used type in industrial applications. For application specific motors, it is very important to select the right bearings and bearing arrangements to optimize performance for the specific application operating conditions. ZZ’s expertise in this field could add further benefits with significant improvement in motor reliability and performance, thus improving machine profitability.

ZZ bearings for industrial electric motors

Longer service life, smaller motors, no re-lubrication, low vibration, energy saving, low weight and low heat generation all can find their answer in ZZ’s full range of bearings.

Improper lubrication or relubrication will lead to excessive wear and shortened bearing service life. Even premature bearing breakdowns might occur resulting in substantially increased operation costs. For optimal reliability and long service life, lubrication is crucial. Either grease or oil can be used as lubricant. Grease should be used when simplified maintenance, improved cleanliness (i.e. fewer leaks) and better protection against contamination are required. However, to meet all demands in the same time is not an easy job. As grease is composed of base oil, thickener and additives, it is important to select optimum composition for such performance requirement. Oil lubrication should be used where normal operating temperatures are high as a result of an external heat source or excess heat generated by the machine itself in high speed applications. Industrial electric motors are usually hard to access, which makes maintenance procedures difficult. Fully automatic lubrication systems can be specified by ZZ, to attain maximum bearing service life and lower operating costs.

Proper sealing is also an important part of the bearing lubricating function. ZZ offers a range of sealed bearings that will improve cost-effectiveness and reduce the total cost for the application.

Longer service life, smaller motors, no re-lubrication, low vibration, energy saving, low weight and low heat generation all can find their answer in ZZ’s full range of bearings.

Improper lubrication or relubrication will lead to excessive wear and shortened bearing service life. Even premature bearing breakdowns might occur resulting in substantially increased operation costs. For optimal reliability and long service life, lubrication is crucial. Either grease or oil can be used as lubricant. Grease should be used when simplified maintenance, improved cleanliness (i.e. fewer leaks) and better protection against contamination are required. However, to meet all demands in the same time is not an easy job. As grease is composed of base oil, thickener and additives, it is important to select optimum composition for such performance requirement. Oil lubrication should be used where normal operating temperatures are high as a result of an external heat source or excess heat generated by the machine itself in high speed applications. Industrial electric motors are usually hard to access, which makes maintenance procedures difficult. Fully automatic lubrication systems can be specified by ZZ, to attain maximum bearing service life and lower operating costs.

Proper sealing is also an important part of the bearing lubricating function. ZZ offers a range of sealed bearings that will improve cost-effectiveness and reduce the total cost for the application.

ENQUIRY