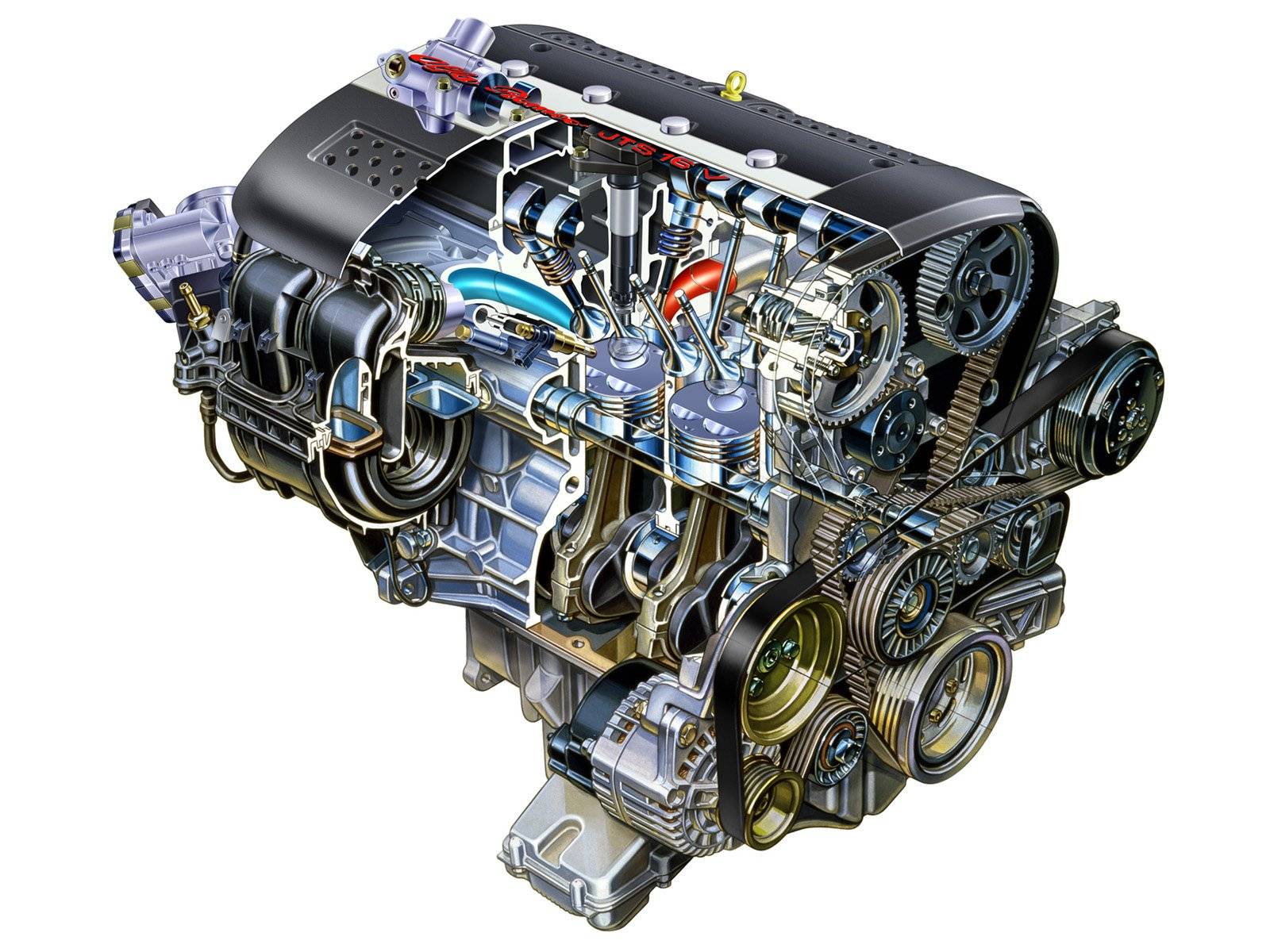

Bearings for Engine system

Today’s petrol (gasoline) and diesel engines are highly sophisticated and computer regulated devices. The substantial gains seen in recent years in economy and emission levels have been, in the main, due to the very complex and detailed control provided by modern ECU engine management systems. For most of cars, gasoline engines are applied. However, for many heavy vehicles, diesel engines are widely applied.

Cooling system, pumps and fans-- Electric cooling fan motor for engine radiator and air conditioning condenser

Air-conditioning condenser and engine radiator are typically grouped together as a unit at the front of the engine compartment. Automatic air-conditioning systems require efficient and frequent condenser cooling. However, high demands for reduced fuel consumption, longer service life and extended warranty periods impose higher requirements on engine thermal management. Therefore, recent developments further focused on electric water pumps, motorized fans between engine and radiator, as between heater matrix and the vehicle’s interior. Usual performance features requested for engine radiator and air-conditioning condenser cooling fan motors are:

> Compactness

> Silent running

> Mechanical and electric components compatibility with frequent and occasional severe contamination

> Longer service life including systematic running from engine start.

> Low friction torque for saving electric energy particularly at low operating temperatures.

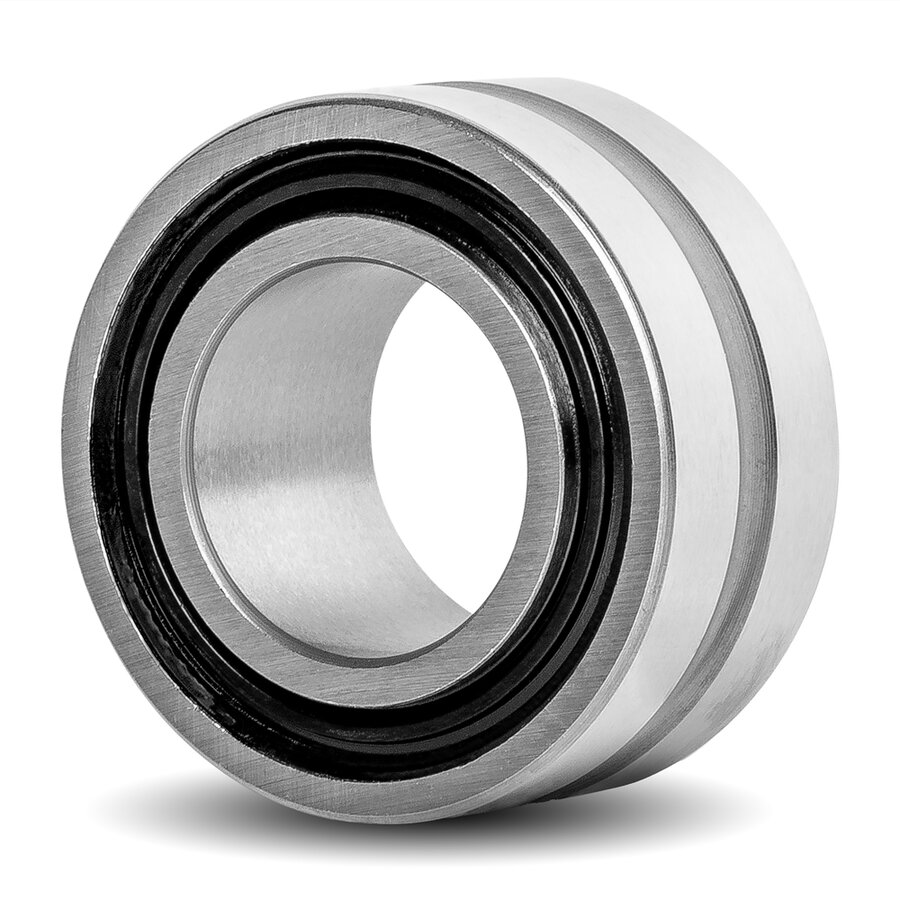

ZZ bearings for cooling system, pumps and fans of engines

ZZ low friction deep groove ball bearings with optimized clearance improve fan running accuracy, power full and silent air flow and contribute to a long service life for the complete motor assembly. ZZ has developed a wide variety of innovative solutions. In our work, we continue to aim at combining reduced fuel consumption, emissions and noise with best performance and cost-effectiveness.

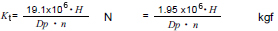

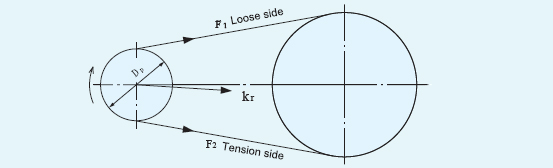

Chain / belt shaft load

The tangential loads on sprockets or pulleys when power (load) is transmitted by means of chains or belts can be calculated by formula:

where,

Kt : Sprocket/pulley tangential load, N

H : Transmitted force, kW

Dp: Sprocket/pulley pitch diameter, mm

For belt drives, an initial tension is applied to give sufficient constant operating tension on the belt and pulley. Taking this tension into account, the radial loads acting on the pulley are expressed by formula. For chain drives, the same formula can also be used if vibrations and shock loads are taken into consideration.

where,

: :

|

Sprocket or pulley radial load, N |

: :

|

Chain or belt factor |

| Chain or belt type |

|

| Chain (single) | 1.2~1.5 |

| V-belt | 1.5~2.0 |

| Timing belt | 1.1~1.3 |

| Flat belt (w / tension pulley) | 2.5~3.0 |

| Flat belt | 3.0~4.0 |

ENQUIRY